| Revision as of 00:31, 18 November 2012 ddgonzal (Talk | contribs) <- Previous diff |

Revision as of 04:57, 4 August 2015 ddgonzal (Talk | contribs) Next diff -> |

||

| Line 1: | Line 1: | ||

| - | The [[Rocker Shaft]] and rocker arms. Also see [[Pushrods]] and [[Lifters]]. | + | The [[Rocker Shaft]] assembly (including the rocker arms) bolts to the cylinder head. Also see [[Pushrods]] and [[Lifters]]. |

| = Overview = | = Overview = | ||

| The stock 1.44:1 rocker arm ratio means that for every 0.100 lift at the camshaft lobe, the valve opens 0.144 inch (less slight flexing of pushrod and rocker arm). | The stock 1.44:1 rocker arm ratio means that for every 0.100 lift at the camshaft lobe, the valve opens 0.144 inch (less slight flexing of pushrod and rocker arm). | ||

| - | * 13257-18003 ROCKER-VALVE (4) $16.25 USD | + | Stock Datsun A-series |

| - | * 13258-18003 ROCKER-VALVE (4) $16.25 USD | + | * 13257-18003 ROCKER-VALVE (4) $16.25 USD |

| + | * 13258-18003 ROCKER-VALVE (4) $16.25 USD | ||

| - | + | Datsun Competition/Nismo rocker arms | |

| - | Datsun Competition/Nismo rocker arms | + | * highlift |

| - | * highlift | + | * large diameter mushroom |

| - | * large diameter mushroom | + | |

| Rockers off the earlier Ford 250 engine have a 1.6:1 ratio and can be resized to fit the datsun rocker shaft. | Rockers off the earlier Ford 250 engine have a 1.6:1 ratio and can be resized to fit the datsun rocker shaft. | ||

| Line 16: | Line 16: | ||

| [[Roller rockers|Roller-tipped rocker arms]] can increase horsepower and reduce valvetrain wear. The low friction of the roller bearings & roller tip lessen the side-to-side wear of the valve guides. Higher ratios like the Datsun Competition rocker arms increase this side thrust force, so using roller rockers seems like a good idea. | [[Roller rockers|Roller-tipped rocker arms]] can increase horsepower and reduce valvetrain wear. The low friction of the roller bearings & roller tip lessen the side-to-side wear of the valve guides. Higher ratios like the Datsun Competition rocker arms increase this side thrust force, so using roller rockers seems like a good idea. | ||

| - | Also see: [[Rocker geometry]] | + | If the head has been skimmed extensively or the block machined down, see: [[Rocker geometry]] |

| + | |||

| + | <img size=400>http://i297.photobucket.com/albums/mm219/ddgonzal/Datsun%201200/wiki/DSCN1957_.jpg</img> [http://i297.photobucket.com/albums/mm219/ddgonzal/Datsun%201200/wiki/DSCN1957_.jpg full] | ||

| + | |||

| + | <img size=400>http://i297.photobucket.com/albums/mm219/ddgonzal/Datsun%201200/wiki/DSCN1955.jpg</img> [http://i297.photobucket.com/albums/mm219/ddgonzal/Datsun%201200/wiki/DSCN1955.jpg full] | ||

| + | |||

| + | <img size=400>http://i297.photobucket.com/albums/mm219/ddgonzal/Datsun%201200/wiki/DSC00258.jpg</img> [http://i297.photobucket.com/albums/mm219/ddgonzal/Datsun%201200/wiki/DSC00258.jpg full] | ||

| + | |||

| + | <img size=400>http://i297.photobucket.com/albums/mm219/ddgonzal/Datsun%201200/wiki/DSC00259.jpg</img> [http://i297.photobucket.com/albums/mm219/ddgonzal/Datsun%201200/wiki/DSC00259.jpg full] | ||

| + | |||

| + | <img size=400>http://datsun1200.com/uploads/photos/16015.jpg</img> [http://datsun1200.com/modules/myalbum/photo.php?lid=16015 album] | ||

| + | |||

| + | <img size=400>http://datsun1200.com/uploads/photos/504.jpg</img> [http://datsun1200.com/modules/myalbum/photo.php?lid=504 album] | ||

| == High-Ratio Rocker Arms == | == High-Ratio Rocker Arms == | ||

| Line 43: | Line 55: | ||

| This little build tip has been a very cheap and effective solution to a problem that only applies to high-lift high-load high-rpm engines. | This little build tip has been a very cheap and effective solution to a problem that only applies to high-lift high-load high-rpm engines. | ||

| - | [http://datsun1200.com/modules/myalbum/photo.php?lid=8677 http://datsun1200.com/uploads/photos/8677.jpg] | + | Spacers for high-RPM operation |

| + | <br>[http://datsun1200.com/modules/myalbum/photo.php?lid=8677 http://datsun1200.com/uploads/photos/8677.jpg] | ||

| [[Category:Valvetrain]] | [[Category:Valvetrain]] | ||

Revision as of 04:57, 4 August 2015

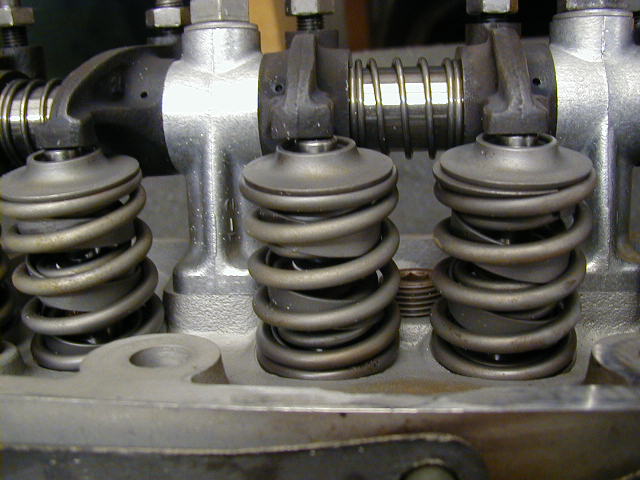

The Rocker Shaft assembly (including the rocker arms) bolts to the cylinder head. Also see Pushrods and Lifters.

Overview

The stock 1.44:1 rocker arm ratio means that for every 0.100 lift at the camshaft lobe, the valve opens 0.144 inch (less slight flexing of pushrod and rocker arm).

Stock Datsun A-series * 13257-18003 ROCKER-VALVE (4) $16.25 USD * 13258-18003 ROCKER-VALVE (4) $16.25 USD

Datsun Competition/Nismo rocker arms * highlift * large diameter mushroom

Rockers off the earlier Ford 250 engine have a 1.6:1 ratio and can be resized to fit the datsun rocker shaft.

Roller-tipped rocker arms can increase horsepower and reduce valvetrain wear. The low friction of the roller bearings & roller tip lessen the side-to-side wear of the valve guides. Higher ratios like the Datsun Competition rocker arms increase this side thrust force, so using roller rockers seems like a good idea.

If the head has been skimmed extensively or the block machined down, see: Rocker geometry

High-Ratio Rocker Arms

Datsun Competition (Nismo) stock-type rockers (1.54:1) and Rocker rollers are available in more extreme ratios than the stock 1.44:1 rocker arm ratio. This means that at maximum opening, the valves open further than with the stockers.

When using these rockers, there are two things that should be checked before installing:

- Valve-to-piston clearance - this is in addition to the normal valve stem clearance check (Valve adjustment)

- Clearance in the valve spring/collet/spring seat area (Spring coil bind) and retainer-to-guide or guide seal clearance

We all know that sometimes even a few thousands of an inch clearance can make all the difference between success and engine damage.

If a high-lift camshaft is being fitted, it is doubly important to check these clearances.

Piston-to-valve static clearance should be between 0.060 inch for a stock-cammed street engine to 0.080 or more for a high-lift cam racing engine. Remember that the valves grows a little bit as they warm up. Clearance is most often adjusted by machining the valve pockets in the piston face a bit deeper. This may also need to be done if you mill the cylinder head. This is usually only a problem with Flat-top pistons.

High RPM

The only place the little race A series is fragile is in the design and wall thickness of the original rocker shaft. It is a thin wall tube that has plugged ends and allows oil to be fed to the rocker bores. Over time the mounting posts can soften and deform causing the rocker to bind simply because the rocker shaft has become out of round. The extra lift and load of big cams only makes this worse.

When assembling your top end and check that you have zero rocker bind once the posts are torqued up. If there is a problem you might have to use a little loctite on the post bolts and reduce the torque setting on individual bolts to ensure no deformation of the rocker shaft Outside Diameter.

You can machine up some rocker spacers to ensure good oil pressure at the rocker bores. They replace the end float springs in the stock design, and when set up right ensure the centreline of the rocker is directly over the centreline of the valve head (see Rocker geometry).

This little build tip has been a very cheap and effective solution to a problem that only applies to high-lift high-load high-rpm engines.

![[Datsun 1200 encyclopedia]](/wiki/upload/wiki.png)