Nissan South Africa sells brand-new steering gearbox units.

Datsun B310 uses a seperate column and gearbox with a flexible coupling. So it is not a direct replacement for vintage B110s.

Rack And Pinion Steering

Consensus:

- NOT recommended for circuit or road racing

- Recommended for Drag Racing

- Jury's out on how well it works for a street car. Those who have done it report good success, those who haven't say the engineering does not add up. See the Considerations section below

Discussions: * 1200 steering box rebuild/replace - what options? * Rack and pinion steering for Datsun 1200

Has anyone ever done it? Yes...

- Race cars with front tube frame (custom suspension and steering geometry)

- dat383 has fitted rack and pinion steering to a 1200 drag racer

- 1200 with full Escort front suspension (rack + struts + steering arms matched)

- wards fitted a Nissan Micra box to his ute

- maddatto is experimentng on a KB Laser fitment

- Bob Cooper fitted a Mini rack to his Datsun 1200

- Janspeed racing 1200, Mini rack?

- 1200 Coupe rally car from UK

There are several Datsun 510s with rack and pinion steering swaps. One uses a rack from a Datsun 200SX. Here's what he did:

- Move the engine crossmember back a couple inches (which necessitates changes to the engine mounts)

- Weld simple flat brackets to the x-member so the rack can be bolted on

- Cut the tie-rod ends and weld them back shorter (make sure you have an expert welder do that). For proper handling, they need to be exactly the same length overall as the A-arm overall lengths

- Use a newer steering column that has a flex-joint on the end. He used a 200SX column.

The swap had three u-joints and a fairly big angle from the end of the column to the rack, but he said it works great, much better than the stock 510 steering box. No slop!

Would it be better to cut the steering arms shorter and rethread them for the tie-rod ends?

I agree this project is not for a novice , I have changed my approach many times as i have discovered pluses and minuses in my geometry , as with any motorsport catergory it's a compromise to achieve a workable result . My aim is to build in as much adjustability as possible to try to cover all bases .

Swap Information

Dat383 used a Holden Gemini (Isuzu) steering rack in front of the crossmember.

- Brackets are fabricated and welded to the crossmember. Because this fits to the front of the crossmember, while the Datsun steering was behing the xmember, swap the complete strut/brake/LCA assemblies from left to right.

- Shortened the Gemini rack ends and then re-thread them to suit.

- The front radius arms needed to have a bend pressed into them to clear the tie rod ends when the suspension is on the bump stops.

- Modify the standard 1200 steering colum to suit:

- Cut the outside of the column at the steering box and fabricate a plate out of steel, using the original rubber locator as a guide.

- Drill a hole in the plate the same size as the outer diameter of the column

- Weld the plate to the column.

- With the modified column fitted to the car and the inner steering shaft coming out, make a short steering shaft with two small uni-joints to join the colum and rack together.

Considerations

For street cars, it is safety first. For safety, you wish to a small amount of Bump Steer to induce slight understeering. For circuit race cars or rally, you probaly won't win without excellent (and fast) handling. But drag racing vehicles don't need to have "good handling" vehicles -- they just need to go very straight. So steering gearbox swaps are popular on these cars, precise geometry is not important on a drag racer.

To do a steering gear swap "correctly" for proper handling, the following must be done:

Bump Steer

- To prevent excessive bump steer the ends of the gearbox linkage (where it meets the tie rod ends) must be equal to the distance between the inner rod ends on the (original) drag link.

- No bump steer may contribute to oversteer in some cornering conditions. With race cars this is OK (and racers will tune out excessive oversteer in others parts of the suspension), but a street car wants a slight understeer to help prevent easy spinouts. A typical value is two degrees per metre for the front wheels.

- Excessive bump steer causes the steering heel to jerk when going over bumps

- NOTE: Many factory cars have a bit more bump steer than needed due to engineering compromises.

- The up-and-down relationship of the new gearbox matters. It should be in the same plane as the ends of the Steering Knuckles during actual driving

- Bump steer can be made more toe out in jounce by lifting the rack if the rack is in front of the axle. The reverse applies if the rack is behind the axle. Usually only small adjustments (say 3mm) are required.

- For race cars, the designer may choose to match this to a cornering condition, or something other than "normal driving"

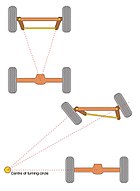

Ackermann steering geometry

- For good conering, precise Ackermann steering geometry agles of the steering arms is required. True ackerman is where the steering arms point to the mid-point of the rear axle centerline. This is most important for low-speed cornering.

-

- This is important for gearbox swaps as well as Strut Swaps

-

![[Datsun 1200 encyclopedia]](/wiki/upload/wiki.png)