<-- back to Owners manual

Air Pollution Control Systems is a section in the Datsun 1200 owners manual.

Pollution control started in the 1960s with the blowby-fume control system (the CRANK system). For the 1971 model year in the USA, two systems were incorporated: EXHAUST and EVAPO. These were incorporated by Japan and Australia by 1975.

1972 USA Owners manual (Page 28 ... 31):

These systems are highly effective in reducing air pollution.

These systems are highly effective in reducing air pollution.

Contents |

Introduction

ARE YOU FAMILIAR WITH THE AIR POLLUTION CONTROL SYSTEMS YOUR DATSUN IS EQUIPPED WITH ? IF NOT, IT IS IMPORTANT TO FIND OUT WHAT THEY ARE AND WHAT HAS TO BE DONE TO KEEP THEM FUNCTIONING PROPERLY.CAUSES OF AIR POLLUTION

Even in the most modern engines, complete combustion is, at present, practically impossible. Inevitably, some of the fuel escapes as a gaseous residue and is discharged into the atmosphere through the exhaust system. These gases along with evaporation from the fuel tank and carburetor, are the primary causes of air pollution by automobiles.

WHAT THE MANUFACTURER SHOULD DO TO REDUCE AIR POLLUTION, AND WHAT YOU SHOULD DO IN COOPERATION

In the foregoing, we have briefly explained how air pollution is caused by harmful gases emitted from automotive engines. The control of air pollution largely depends upon the development of effective air pollution control systems. To meet this demand, NISSAN MOTOR Co. has been making continuous efforts day and night for development of such devices.

Your car is equipped with the air pollution control systems that have resulted from an intensive research and development program. These systems are highly effective in reducing air pollution. Further control is expected with your attention to the following caution: The air pollution control systems Installed in your DATSUN Car are outlined in the following paragraphs, with some notes of their maintenance.

Have the systems checked and tuned up periodically by a NISSAN-authorized dealer.

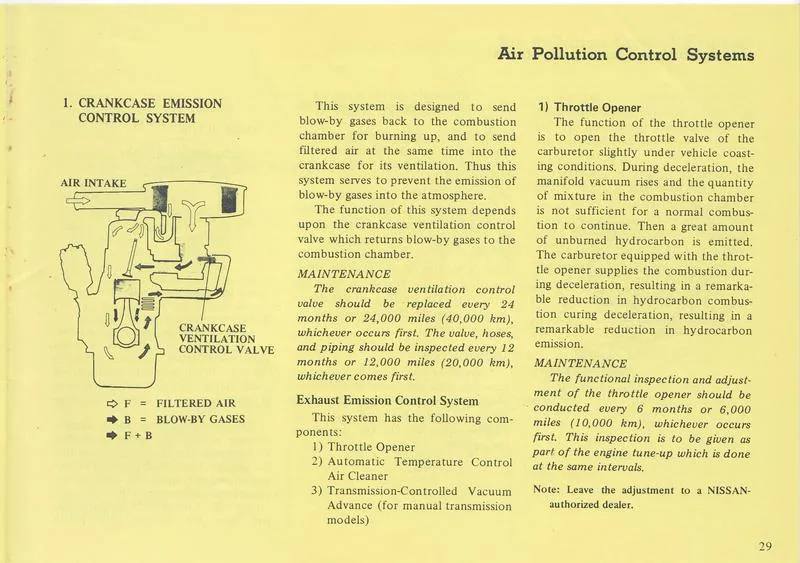

Crankcase Emission Control System

1. CRANKCASE EMISSION CONTROL SYSTEMThis system is designed to send blow-by gases back to the combustion chamber for burning up, and to send filtered air at the same time into the crankcase for its ventilation. Thus this system serves to prevent the emission of blow-by gases into the atmosphere. The function of this system depends upon the crankcase ventilation control valve which returns blow-by gases to the combustion chamber.

MAINTENANCE

The crankcase ventilation control valve should be replaced every 24 months or 24,000 miles (40,000 km), whichever occurs first. The valve, hoses, and piping should be inspected every 12 months or 12,000 miles (20,000 km), whichever comes first.

Exhaust Emission Control System

Exhaust Emission Control SystemThis system has the following components:

- Throttle Opener

- Automatic Temperature Control Air Cleaner

- Transmission-Controlled Vacuum Advance (for manual transmission models)

Throttle Opener

1) Throttle OpenerThe function of the throttle opener is to open the throttle valve of the carburetor slightly under vehicle coasting conditions. During deceleration, the manifold vacuum rises and the quantity of mixture in the combustion chamber is not sufficient for a normal combustion to continue. Then a great amount of unburned hydrocarbon is emitted.

The carburetor equipped with the throttle opener supplies the combustion during deceleration, resulting in a remarkable reduction in hydrocarbon combustion during deceleration, resulting in a remarkable reduction in hydrocarbon emission.

MAINTENANCE

The functional inspection and adjustment of the throttle opener should be conducted every 6 months or 6,000 miles (10,000 km), whichever occurs first. This inspection is to be given as part of the engine tune-up which is done at the same intervals.

Note: Leave the adjustment to a NISSAN-authorized dealer.

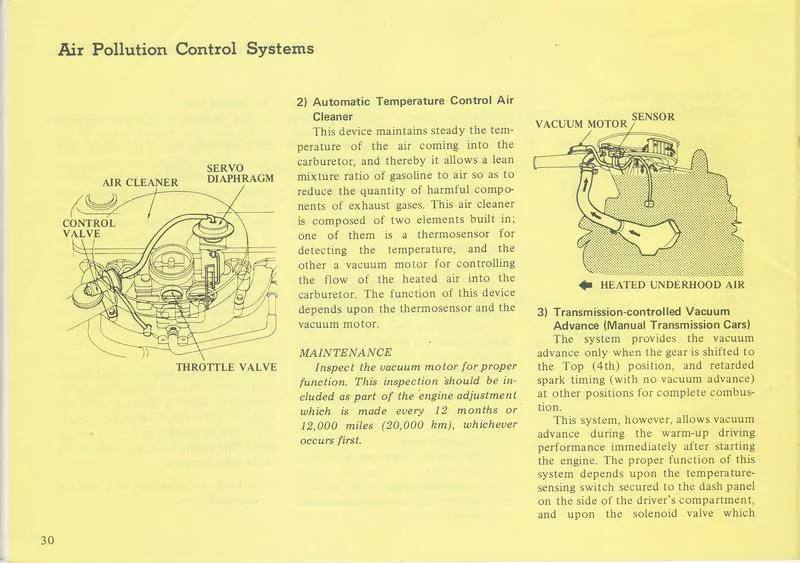

Automatic Temperature Control Air Cleaner

2) Automatic Temperature Control Air CleanerThis device maintains steady the temperature of the air coming into the carburetor, and thereby it allows a lean mixture ratio of gasoline to air so as to reduce the quantity of harmful components of exhaust gases. This air cleaner is composed of two elements built in; one of them is a thermosensor for detecting the temperature, and the other a vacuum motor for controlling the flow of the heated air into the carburetor. The function of this device depends upon the thermosensor and the vacuum motor.

MAINTENANCE

Inspect the vacuum motor for proper function. This inspection should be included as part of the engine adjustment which is made every 12 months or 12,000 miles (20,000 km), whichever occurs first.

Transmission-controlled Vacuum Advance

3) Transmission-controlled Vacuum Advance (Manual Transmission Cars)The system provides the vacuum advance only when the gear is shifted to the Top (4th) position, and retarded spark timing (with no vacuum advance) at other positions for complete combustion.

This system, however, allows vacuum advance during the warm-up driving performance immediately after starting the engine. The proper function of this system depends upon the temperature-sensing switch secured to the dash panel on the side of the driver's compartment, and upon the solenoid valve which advances the ignition timing by con- ducting vacuum, The controls used in this system are shown in the below illustration.

Note: The Top gear (4th) switch actuates only when the transmission is shifted to 4th gear.

MAINTENANCE

Examine the transmission-controlled vacuum advance for proper function, Its maintenance is to be performed every 12 months or 12,000 miles (20,000 km), whichever occurs first.

Note: The engine service points indicated in the "Periodic Maintenance and Lubrication Schedule" of this manual should be checked and adjusted at the respective intervals as designated.

Evaporative Emission Control System

2. EVAPORATIVE EMISSION CONTROL SYSTEMThis system prevents gases from going out from the fuel tank into the atmosphere. When pressure in the fuel tank is increased due to evaporated fuels over the predetermined value, the flow guide valve opens to send the gases to the crankcase. Then the gases are guided into the combustion chamber by the crankcase emission control system.

When pressure in the fuel tank is decreased due to consumption of fuel, filtered air is then delivered to the fuel tank. In this manner, the ventilation of the fuel tank is accomplished.

MAINTENANCE

Check the flow guide value for the proper function, and check the hoses, connectors and piping to find out if there is any leakage. This maintenance check is to be done every 12 months or 12,000 miles (20,000 km), whichever comes first.

![[Datsun 1200 encyclopedia]](/wiki/upload/wiki.png)