This article is about the stock Hitachi carb, model Hitachi DCG-306 (manual choke) and DGH-306 (auto choke). However, much of the following generally applies to other standard venturi carbs like Weber carbs. But it doesn't discuss SU-type carbs like the Hitachi Sidedraft Carburetors used on the 1200 GX models.

A prime focus of this article is: how to avoid buying parts you don't need. Instead, find the problem and fix it, or replace only what's actually bad. It's likely you can solve most problems without spending money replacing any parts. Rarely do cap, rotor, plugs, etc. need replacing, or even a new carb or rebuild kit be required. Even with used parts it should still run smooth. The points and condensor are the most likely to go bad, and a dwell meter will help tell the story there.

Contents |

Where do I get a repair manual?

- eBay, usually for less that $10 USD. NOTE: Clymer, Chilton, etc general repair books include detailed carburetor info

- new, a Chilton manual is around $15 USD, try Amazon.com

- public library

- For a non-stock carburetor, there are books specifically for Weber, SU, etc carburetors

What to Check First - Float Level

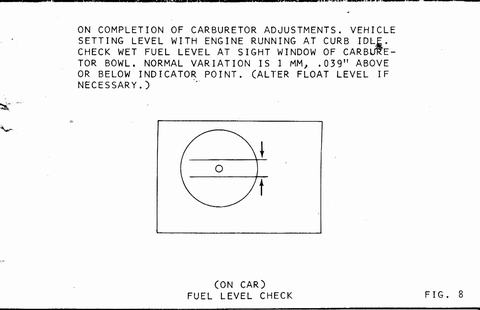

Easy Tip! - check Float Level. An extra-nice feature of the Hitachi is the float glass site-level. When running, look through the float glass and ensure the level of the fuel is right. It should be near the center line of the glass. If not, you'll need to take the carb apart to adjust the float level.

- If it's too high, the carb can flood and/or run rich

- If it's too low, it can run lean, hesitate (flat spot) or even run out of fuel on hard cornering!

- This can be adjusted independent of the other steps

There is a dot in the center of the glass. With engine running, the fuel level should be very close to the centerline of the glass. If it's high or low, you need to adjust the float level as your first carb-adjustment step.

Check Fuel-level site glass. Instructions are below in the Float Level section.

IMPORTANT: High fuel pump pressure can cause a high float, so perform the Fuel pump pressure test first -- before taking the carb apart to adjust the Float Level.

Engine Compression

If your engine has bad compression, you'll probably want to repair that first.

- If the compression is evenly low, you should be able to make your carb run better by continuing with the carb adjustment

- If only one or two cylinders have low compression, it won't help to adjust the carburetor. You must perform engine repair.

Step 1: Perform Engine compression test.

Each cylinder should be between 110-150 lbs pressure. Some variation is OK, but all cylinders should be within 25 lbs of each other. If one cylinder is 90 psi or below suspect bad rings or a burnt valve. In this case, adjusting the carb probably won't fix all the problems.

Engine Timing

Before touching the carburetor, make sure your engine Ignition Timing is right. This is the foundation of adjusting the carburetor. If this is off, adjusting the carburetor may not make the engine run any better. Also, timing problems might appear to be carb problems, so do this first to make sure.

Step 2: Perform Ignition Timing adjustment.

Check for Vacuum Leaks

Wait a minute! When do I get to adjust the carburetor?

Good question, but remember: Vacuum Leaks are your Worst Enemy -- they are a most common problem causing bad carburetor performance, if not the most common problem. So spend some important time on finding vacuum leaks.

Some people call vacuum leaks "air leaks".

Leaking intake gaskets and carb gaskets are not the most common problems. More often:

- broken hose ends

- leaking vacuum motors (diaphragms)

The vacuum motors are:

- Vacuum Advance

- Choke Pull-off (automatic choke models)

- Air Cleaner heat-flap Motor (some engines)

- Carburetor Dashpot (some engines)

- EGR Valve (newer engines)

- on the carb:

NOTE: Only a few of the vacuum devices are actually powered at idle. The others only activate at certain temperatures or other conditions. So we will concentrate on other tests first.

The next section will show how to look for vacuum leaks.

Engine Off Inspection

Perform these steps before starting the engine.

Examine Hoses

Examine carefully all the vacuum hoses on the engine, especially the ends of each hose. Cut off cracked ends and refasten. This will fix or help prevent vacuum leaks at the hose ends.

Check the Play on the Throttle Shaft

With old carbs, this is also a critical wear spot. When buying a used carb, this is the most important thing to look for.

Wiggle the throttle shaft from side to side (90 degrees to the shaft). Wear is common with old carbs. It should feel tight with no discernible play. A worn shaft makes a vacuum leak: the engine idle rough, even to the point of killing the engine at stops and it can not be tuned to idle correctly.

- It should be tight, and if so no worries

- If it's loose, it needs to be drilled and bushings put in. See Carburetor Repair 2.

Accelerator Pump Test

Here's how the accelerator is supposed to work, whenever you open the throttle (depress the accelerator pedal):

- a little fuel is squirted direct into the carburetor throttle bores (running or not)

- if you do this too many times before starting the engine, you will "flood" the engine and it won't start until you let it sit for a while (give it time to let the fuel evaporate)

- if the accelerator pump (plunger) isn't working, the carb will idle, but not accelerate to a higher speed very well (if at all)

- if the accelerator pump is only partially working (only squirts a small stream), when accelerating the engine will 'hesitate', 'buck' or backfire

TIP: Old carbs from the 60s and 70s had leather pump gaskets, which dry up if fuel isn't kept in the carb. Sometimes when starting a carb that hasn't run in years, letting it sit a few days will let the seal expand, but other times it needs replacing.

Here's how inspect the accelerator pump:

- With engine off, take the air cleaner off

- Hold the choke open and look down into the carburetor

- Turn the throttle shaft or have someone "floor" the accelerator pedal

- You should see a definite smooth squirt of fuel from near the top of the throttle bore down into the bore

- If none is seen, or if it's intermittent, replace the accelerator pump inside the carb (see Internal Inspection section)

Vacuum Motor Testing - Engine Off

Here are some ways to check for vacuum leaks in the vacuum motors (diaphragms) with the engine off:

Use Your Finger Method

Test each diaphragm. Here's an example using the choke pull-off

- Pull the hose off the choke pull-off

- Use a screwdriver to push on the rod coming out of the pull-off

- Cover the port with your finger

- Let go of the screwdriver. The rod should stay pushed in

- Take your finger off.

The rod should stay or maybe move back just a little.

- If it moves all the way back, the diaphragm is leaking. Plug the hose until you can replace the pull-off (it only works when the engine is cold anyways -- if bad, it causes the engine to "chug" after first starting it)

Repeat for these diaphragms:

- Throttle opener

- Distributor Vacuum Advance

- Carburetor dashpot (some engines)

- EGR Valve (newer engines starting with B210). CAUTION: This gets very hot, so only test with engine Cold!. With some EGR valves, you can push the diaphragm with your finger. With others you cannot. Alternative: You can plug the valve to see if the engine drives better. For a non-street engine, plug it permanently; it is for emissions only and affects performance negatively

- Carburetor dashpot (some engines)

NOTE: Newer carbs/engines/distributors may have even more diaphragms to check:

- Distributor retard. Test in same way as Vacuum advance. For a non-street engine, plug it permanently, as it degrades performance

- Other Emission controls

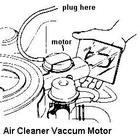

Air Cleaner Motor

Some engines have an Air Cleaner Motor. If needed, this part can be replaced OR can be left plugged. This is the hot-air flap, and is only strictly necessary in cold climates (temps close to freezing) to prevent carburetor frost-up.

Air Cleaner Hot Air Valve

Air Cleaner Hot Air Valve

It is very common for the Air Cleaner Motor to leak. You can push up on this after removing the hot air tube and check and see if it holds vacuum. This part is only needed in cold-weather operation, to keep the carb from icing over.

Alternative test: check on a warmer day that this is closing (some cold air is entering, not all hot). Plug the hose if it is not working correctly. The flap should not open all the way until 122 degrees Farenheit.

Vacuum Gun Method

Use a vacuum-making hand gun. It will come with instructions and costs around $50 USD. This is the easiest, most accurate and best way to do it. Basically, you pull the hose off the vacuum motor, connect the gun, and squeeze the trigger. A built-in vacuum gauge will tell you if vacuum is holding.

You can also test small emissions parts with this tool. Some parts are designed to hold a partial vacuum (a repair manual will have more details on testing these parts).

- Push on the motor's rod or diaphragm with your finger or a screwdriver.

- Use another finger on the port to block the hose

- While still blocking the hose, release the shaft or diaphragm

- With your finger covering the port, the motor should stay fully or partly in position. This part is good.

- If it immediately moves back to normal, it's leaking. Replace the part. Some parts can be blocked off (put a golf tee in the hose)

Parts that can be blocked temporarily and still get good performance include:

- EGR valve. Replace the bad part to help maintain low emissions

- Distributor advance. It will run slightly jerky blocked, but it is better than leaking

Choke Test – Engine Cold

See the Choke Operation page.

Engine Idling Tests

Start the engine and let it idle. We will now check for vacuum leaks. Only a few of the vacuum devices are actually powered at idle. The others only activate at certain temperatures or other conditions. So these are some you can test at idle.

Float Level Inspection

If the float level is incorrect, you will need to partially disassemble the carburetor. See Float Level Adjustment page.

Vacuum Testing - Choke Pull-Off

Temporarily disconnect and plug the hoses that go to the choke pull-off to see if it makes a difference. Just put a golf-tee or something to tightly plug the end of the hose. If the engine idles faster with host intact, but slower with the hose plugged, it indicates a leak).

choke and throttle vacuum motors

choke and throttle vacuum motors

PCV Valve Test

Plug temporarily the hose going into the PCV valve (in the manifold, just under the carb) to see if the engine slows way down -- more than a little. This hose is difficult to get off, though if it isn't too stiff, you might be able to squeeze it shut with pliers. If it does lower the idle speed significantly, remove and clean (or replace) the PCV valve.

Leak Test - Gasket Junctions

If no leaks have shown up yet, spray the carb-manifold junction and the intake manifold-head junction with WD40 -- if is smooths out while spraying a particular spot, tighten the bolts or replace the gasket. The idea here is that the oil temporarily plugs the leak and you can hear the engine run differently.

CAUTION: Don't over-torque the bolts. That won't help, and potentially can break the bolt off.

LPG Vacuum Leak Test

Professional mechanics check for vacuum leaks by using a bit of LPG. (thanks to Matt)

- Find a small LPG (Liquified Petroleum Gas, I'm not sure what you'll have) cylinder from a camping stove and fit it with a flexible tube (5/16 fuel hose will do)

- Start the engine and get it idling, then drift a small amount of gas in the carb opening.

- If the engine running smoothes out with additional gas you have got an air leak.

- Now slowly drift gas around the manifold to head surface, carb to manifold, carb etc.

- If as you do this the engine smoothes out that area is where the leak is.

- If putting gas into the carb smoothed the running but no air leaks are found then it is probably a jetting or other carb set up problem.

Anti-dieseling solenoid valve

1973 and newer carbs may have an Anti-dieseling solenoid.

Anti-dieseling valve

Anti-dieseling valve

If this isn't working right:

- Engine won't idle, but drives good otherwise

This valve has one electric wire.

Make sure it's getting power when the ignition is on (engine running or not running, it should have power):

- Disconnect the wire connector

- Turn key to IGN (not Start)

- Listen carefully, while you connect wires together. You should hear a 'click' when connecting. Try it several times.

If no click is heard, replace the valve.

Choke Operation - Engine Warm

See the Choke Operation and Adjustment page.

Idle Speed and Mixture Adjustment

NOTE: Idle speed must be adjusted with engine fully warmed, choke butterfly fully open. Take off air cleaner lid and confirm the choke is fully open before proceeding.

- Adjust curb idle speed. Carburetor Specifications vary, but any stock A-series engine should idle fine at 750 rpm

- Mixture adjustment. Specs vary, but this will make any stock A-engine run nice:

- Adjust idle to 800 rpm

- turn mixture screw in (clockwise) to lean the mixture down to 750 rpm

- Just learning? To get a 'feel' for this adjustment, turn the screw by half turns clockwise and anticlockwise till you hear the engine speed up and slow down. Then fine turn with 1/4 turns. Do this repeatedly until you are confident of the results

- Fast Idle: this is part of the choke adjustment, and isn't done with the engine warm. See the Choke section

![[Datsun 1200 encyclopedia]](/wiki/upload/wiki.png)