| Revision as of 00:58, 22 June 2016 ddgonzal (Talk | contribs) <- Previous diff |

Revision as of 02:10, 12 August 2016 ddgonzal (Talk | contribs) Next diff -> |

||

| Line 1: | Line 1: | ||

| - | Engine ignition timing (distributor spark timing) is the foundation of any tune-up. It is generally the first step you need to perform as all other [[tune-up]] and carburetor adjustments depend on ignition timing being correct. | + | Engine ignition timing ([[distributor]] spark timing) is the foundation of any tune-up. It is generally the first step you need to perform as all other [[tune-up]] and carburetor adjustments depend on ignition timing being correct. |

| For camshaft installation/timing chain orientation, see [[Timing_Chain#Alignment|Timing Chain Alignment]] | For camshaft installation/timing chain orientation, see [[Timing_Chain#Alignment|Timing Chain Alignment]] | ||

Revision as of 02:10, 12 August 2016

Engine ignition timing (distributor spark timing) is the foundation of any tune-up. It is generally the first step you need to perform as all other tune-up and carburetor adjustments depend on ignition timing being correct.

For camshaft installation/timing chain orientation, see Timing Chain Alignment

Contents |

Overview

If you have the distributor out of the engine, see Installing Distributor.

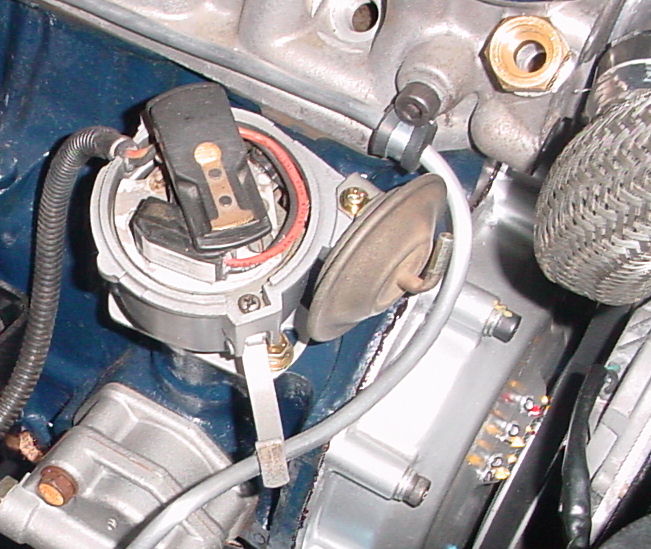

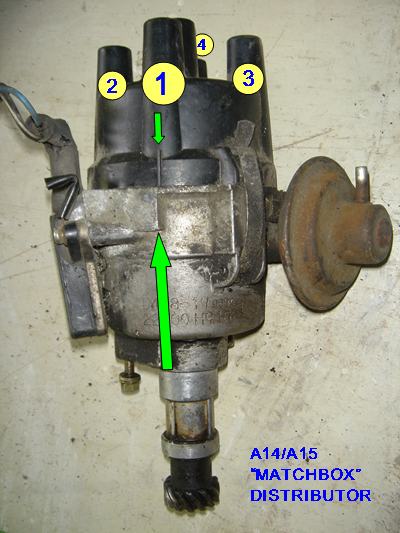

The stock Datsun 1200 distributor orientation

vacuum advance pointing almost straight forward

The exact orientation is not important. Because the A-series has a gear drive, you can set the timing correctly at most orientations as long as the plug wires point to the correct plugs.

General Procedure

- Check the gap on the plugs then put them back in. Spec is 0.028-0.032 inch for the A12. Use 0.035" for the smoothest idle. Re-gap if necessary.

- Set the point-gap or dwell. Use a dwell meter if at all possible as it is much more accurate than the points gap, Set dwell 49 to 55 degrees.

- If the points are brand new, a feeler gauge can be used to set the gap to 0.020 inch. Incorrect Dwell can cause rough running, as does bad points. For example, it might only run at high idle, and not very smooth at that.

- NOTE: If the points are used, do not set them via feeler gauge. They pit during normal operation will which render gap measurement incorrect.

- Double-check the Initial Timing (per section below). Spec is 7 degrees BTDC (5 degrees North America) and safe for any A-series engine. This must be done after setting the dwell -- because changing the dwell affects the timing, but not vice-versa.

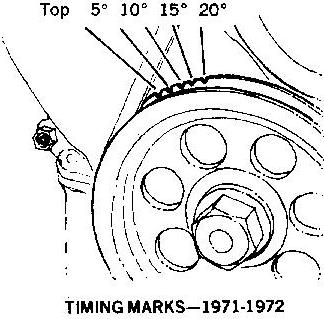

NOTE: If you use the older pulley with the newer cover, then you could get really weird timing readings

Ignition Timing Specifications

With Contact Points

point gap (new points): 0.018-0.021 in (0.45 - 0.55 mm) dwell (new or used points): 49-55 degrees Spark plug gap: 0.31-0.35 in (0.8 - 0.9 mm) static timing: 7 degrees BTDC static timing: 5 degrees BTDC (with north american Distributors)

Late 1200 Electronic Ignition

point gap: Not Applicable dwell angle: Not Applicable Spark plug gap: 0.35 in (0.9 mm) static timing: 7 degrees BTDC

Firing Order

Almost all inline 4s have a firing order of 1-3-4-2 -- and certainly all Datsun fours.

NOTE: If the distributor is out of the engine, see Installing Distributor

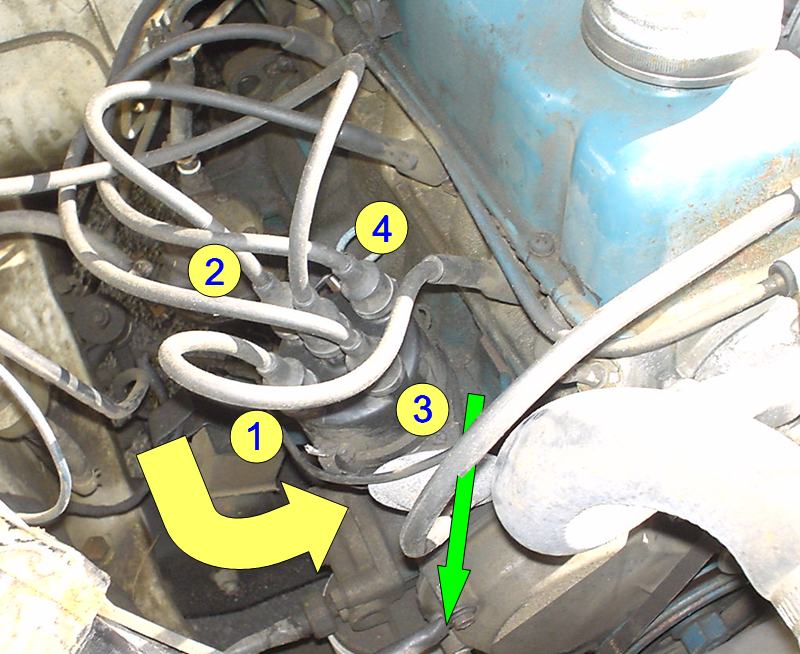

First locate #1.

photo

The direction of rotation (Yellow arrow) is always opposite the direction that vacuum advance points (green arrow) -- for all engines, not just Datsuns.

Next, following the direction of rotation (Yellow arrow), count off 1-3-4-2.

Here is the 1974-up distributor:

Setting Dwell

If your 1200 still has the factory contact points (if you haven't convereted to Electronic Ignition) you must set the dwell for perfect tune. To accurately check the contact points Dwell angle, use a dwell meter. This is far more accurate than simply setting the points-gap.

From the 1973 Factory Service Manual:

- Dwell angle: 49-55 degrees

- Point gap: 0.45 to 0.55 mm (18-22 thousands inch)

NOTE: The same specifications are used for B10, B210 and B310 with contact-point ignition as well.

The gap should be checked every 3,000 miles (5k) as part of a Tune-up.

|

Dwell-Tachometer

Older style (analog) Dwell-Tachometer

- New points are gap-set to 0.018-0.021 inch. In a pinch you can use an old-fashioned matchbook cover, which is typically 20 thousands of an inch thick.

- Check the dwell

- Readjust the gap until it reads 49-55 degrees

NOTE: On this type of scale with only 8- and 6-cylinder, 4-cylinder reading is DOUBLE 8-cylinder scale.

Be patient when setting the dwell. You may need to slightly re-adust the gap and re-check the dwell many times before it is 'right on'. This involves starting and stopping the engine multiple times. But it will be worth it when your 1200 purrs like a lion.

Initial Timing

PREPARATION

Once the dwell is correct set, to check the timing follow these steps:

- turn engine off. Set parking brake. Put transmission in neutral

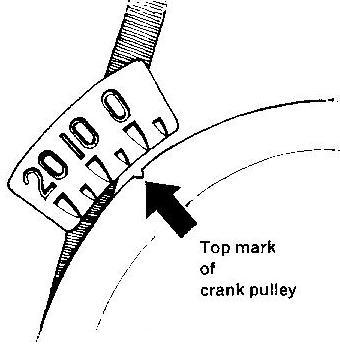

- turn engine by carefully turning fan clockwise, until the timing marks line up (5 or 7 degrees BDTC). If the fan belt slips, you are turning it too fast -- or it's too loose (tighten it!)

- Pull cap off distributor. Is the rotor pointing at the Number 1 spark plug wire OR #4 wire? Good.

With Points

With engine turned to the correct timing mark (as above):

- pull coil wire from cap. Lay atop the engine or strut tower, with the metal lead 1/4 inch from bare metal

- turn Key to IGN (do not start engine)

- Loosen the distributor hold down bolt slightly. Be careful not to rotate the distributor.

- Rotate housing clockwise slightly until points appear closed

- Rotate housing anti-clockwise -- slowly -- until a spark appears at the coil wire

- Tighten distributor hold-down bolt

- Replace cap (ensure rotor still points to #1 or #4)

With Electronic Ignition

With engine turned to the correct timing mark (as above):

- Are the teeth aligned? Good, timing is correct.

If the timing needs adjusting:

- Loosen the distributor hold down bolt slightly. Be careful not to rotate the distributor while doing this

- Rotate housing clockwise slightly until the teeth align

- Tighten distributor hold-down bolt

- Replace cap (ensure rotor still points to #1 or #4)

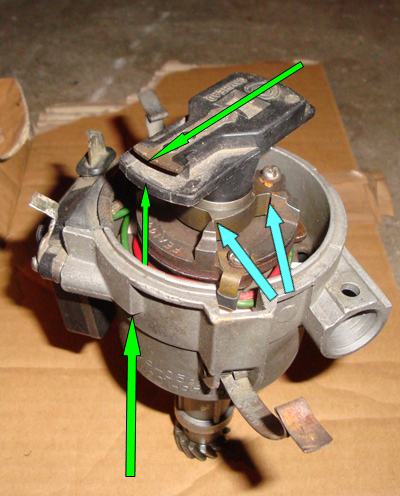

Line up teeth (Vanette, E-series, and Sunny Truck)

Matchbox Type: Line up teeth (blue lines)

Rotor should point to line (180 degrees opposite is OK too)

Setting Timing with Timing Light

Fine-Tuning

Note the timing marks on the A12 plate. These are fine-tuning Advance and Retard marks

These are NOT used to time the engine (the marks on the crankshaft pulley are). But they are very useful for advancing or retarding the timing a degree or two. After installation, you can look down past the #1 spark plug, between the engine and the distributor to view the marks.

- Advance it two degrees (turn distributor clockwise), test drive, repeat until it pings at part throttle

- Retard it one degree (turn counter-clockwise) to remove the pinging

Once you have this, you can note the exact timing and next time use it instead of the factory specification.

Advanced Timing

Base timing

Stock base timing is 7 degrees before top dead center (BTDC).

Stock base timing for EXHAUST emission controlled engines is 5 degrees before top dead center (BTDC). Because this is factored into the distributor curves, do not advance it further at risk of exceeding the maximum advance at high RPM. The emission controlled distributors have more mechanical advance to make up for the lesser base timing.

Tuning for Power

The stock distributors have a mechanical advance tolerance of +- 2 degrees at the crankshaft. That's a huge difference -- up to 4 degrees retarded is still within specs -- and is why you should tune your A12 for power.

Whether a stock engine, or a modified, check this out! You can possibly increase hp AND fuel economy at the same time for free!

See main article: Spark Curve * Dialing in Distributor Spark Curve * Spark Retard, for boosted engines * Fully electronic spark timing

![[Datsun 1200 encyclopedia]](/wiki/upload/wiki.png)