Weber DCOE sidedraft carburetor. The traditional racing carburetor.

Contents |

Also See

* OER (redesigned DOCE-style carburetor) * Choosing A Carburetor

Overview

The great thing about these carbs (as well the Dellorto DHLA) is that the jets are externally accessible, even when the air filter is on. This makes jet changes at the racetrack a snap.

Weber DCOE is a sidedraught carburetor. It uses the same Intake Manifold as Dellorto DHLA or Mikuni PHH.

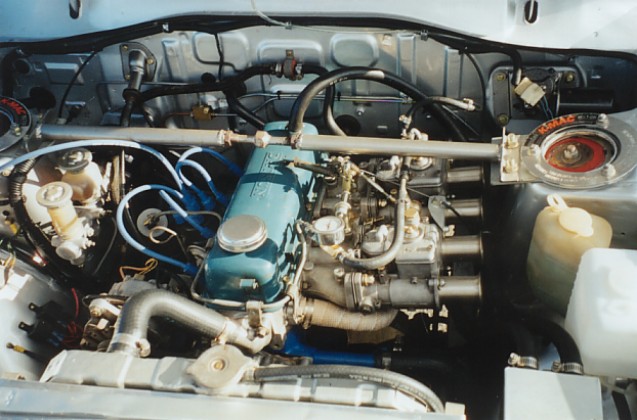

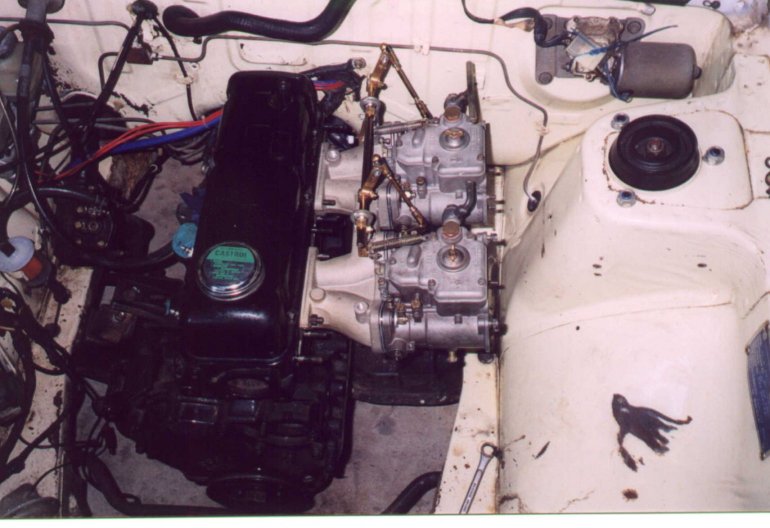

Single Or Twin

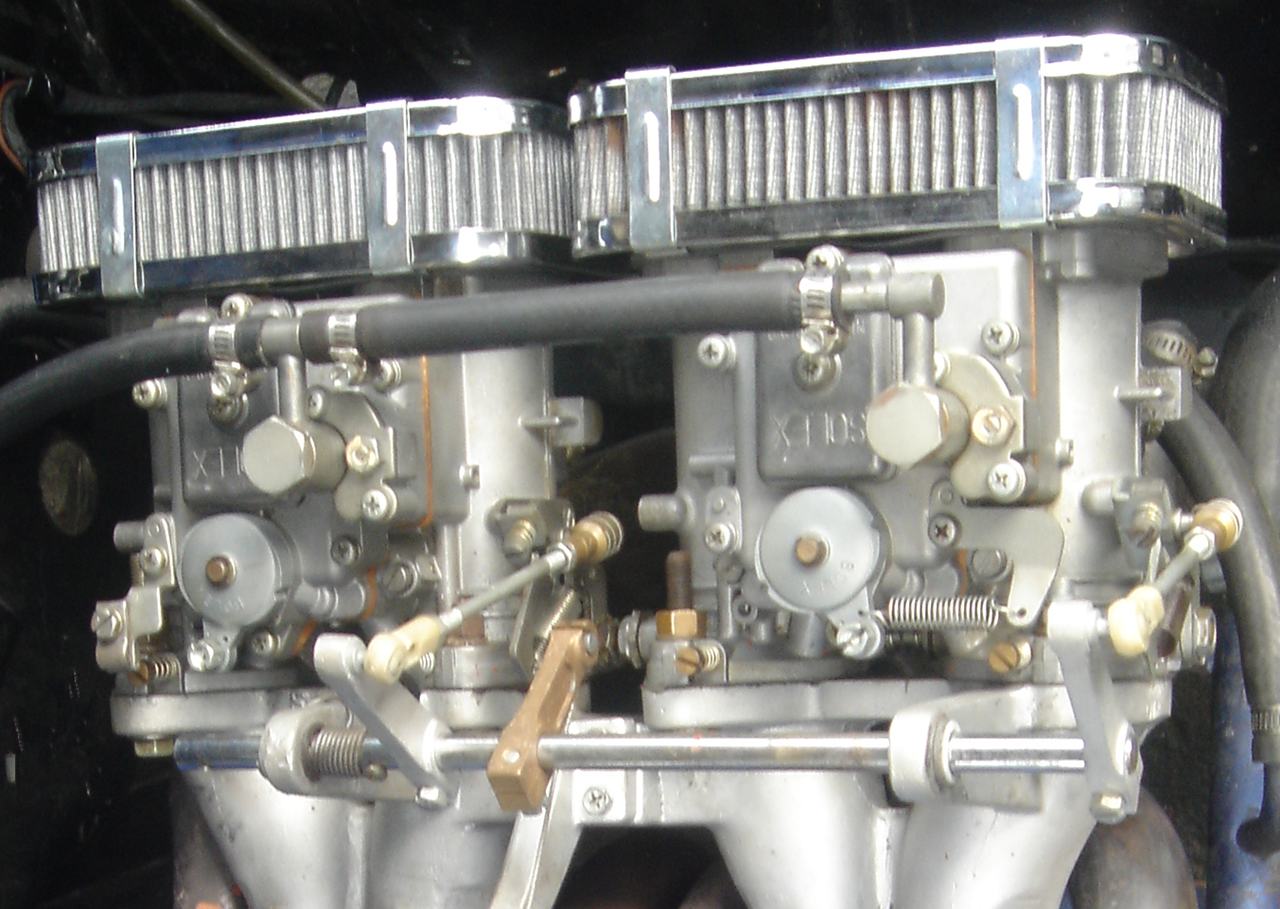

A twin DCOE setup has a huge advantage over the single: ITB (individual throttle bores). 2 DCOE = 4 throttles.

See Choosing A Carburetor: Single or Twin?

Single DCOE

Twin DCOE

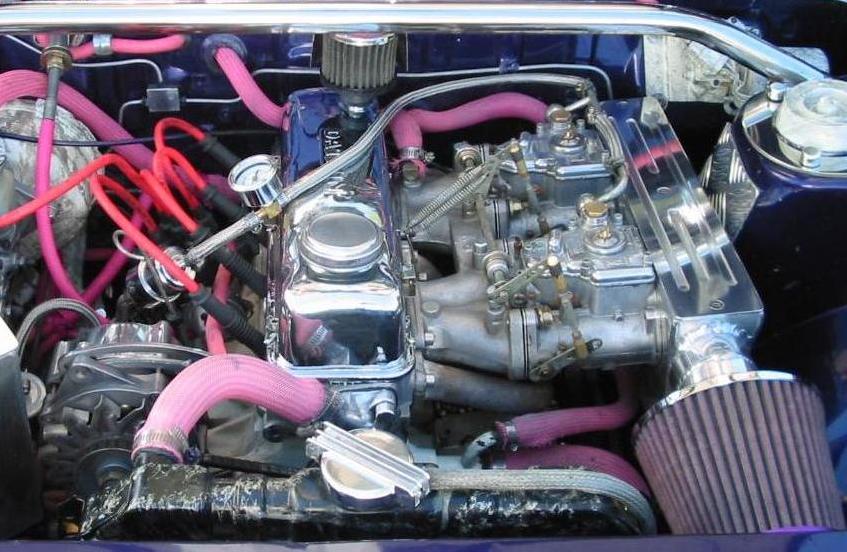

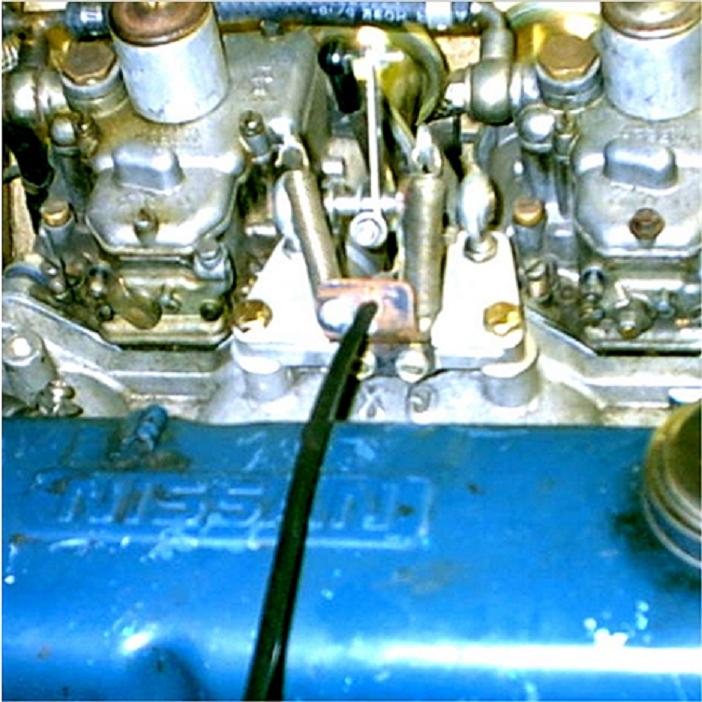

Tomei engine, good view of the linkage

angled manifolds, good for fitting in LHD cars

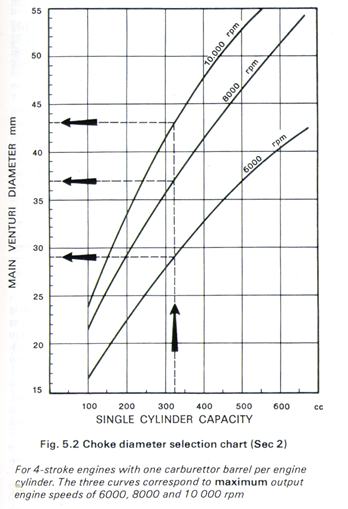

Sizing

DCOEs are available in 40, 42, 45, 48, 50, and 55mm sizes. Most Datsun A-series street engines run the dual 40s. Note that there are different size venturis for the 40s. This "barrel" size (40 or 45) doesn't determine the airflow, which is determined by the size of the main venturi (choke). The 28mm venturi might work best for a street A12, while a 38 venturi would be good for an 8,000 rpm A14.

CHOKES (venturis) * Weber 40: 29mm to 36mm * Weber 45: 32mm to 40mm

Proper sizing is important for good performance: A stock A12 likes a 26-28 mm venturis @ 6,000 RPM.

See main article: Carburetor Sizing

- 8000 RPM A12, calling for 36mm venturis per the chart, you could use either 40s or 45s.

- You can fit 45s to a relatively stock A12 and it will run "OK", but not great. You'll actually make more power with correctly tuned 40s

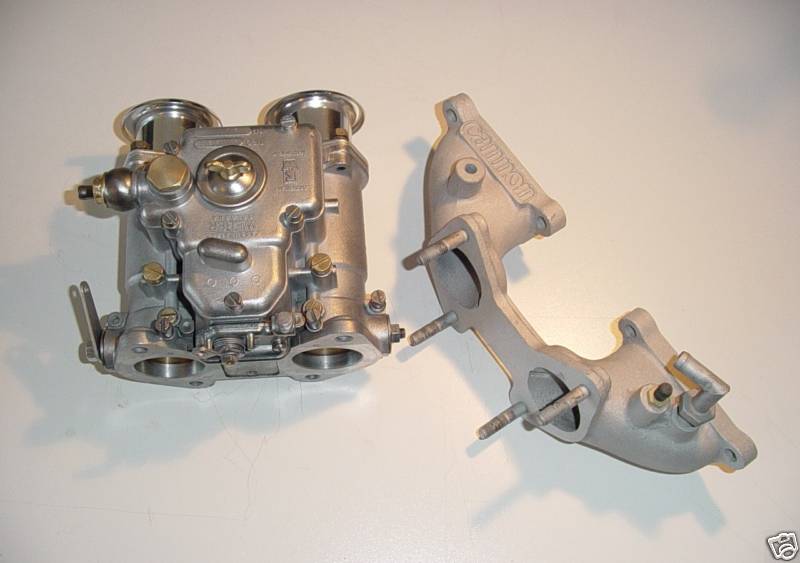

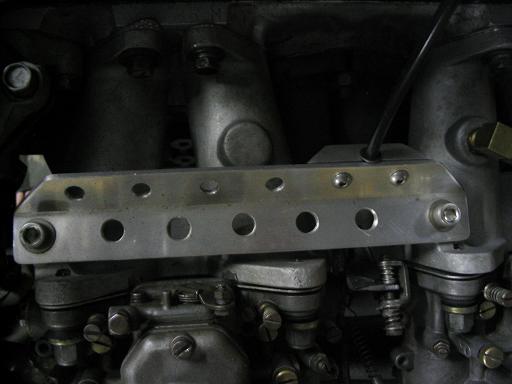

Intake Manifold

Weber DCOE, Dellorto DHLA and Mikuni/Solex PHH use the same manifolds. Single or Twin manifolds are available, for round-port or oval-port A-series engines.

Vacuum Connection

Drill & tap the boss for a tube fitting. Can be used for power brakes, distributor vacuum advance.

Air Filter

Many use simple screens over the carburetor, which keep large objects out of the engine. This (or no screen) provides the fullest "awesome sidedraft sound", but at the expense of increased engine wear.

For filtering, the easiest thing is sock filters, but all sorts of regular and remote filter can be used.

LHD Fitment

Space for twin sidedrafts on LHD 1200s is limited because the brake master cylinder is on the carburetor side of the engine.

Heat Shield

Adjustment

Idle Speed and Mixture Adjustment

- Warm engine fully

- Adjust curb idle speed to 900 rpm

- Slowly turn mixture screw out until the engine speeds up, then keep turning out until engine starts to slow down slightly (overly rich)

- Screw in (clockwise) until engine slows down (lean). Turn back out til it runs fastest (Best Lean)

- Repeat for second barrel of the carburetor

- If a twin-carb setup, repeat for the second carburetor

To get a 'feel' for this adjustment, turn the screw by half turns clockwise and anticlockwise till you hear the engine speed up and slow down. Then fine turn with 1/4 turns. Do this repeatedly until you are confident of the results.

Linkage

Linkage depends in part on the manifold you use. Does it have bolt-bosses for linkage? Or does it have built-in linkage bar?

Side Pull

Tomei manifold Side Pull. Nismo/Tomei manifold have built-in bar towers and use a large diameter cross bar

Center Pull

Center Pull - Need the floating lever for the carburetors. In essence, a single throttle lever, with its own balance screw

Center Pull needs only one carb-pull, eliminating the separate throttle adjustments. The center floating linka has its own balance screw

Single Carb Linkage

Quadrant

Fan lever - Harada Shosho company

Throttle Lever

Universal carby throttle lever

Kits

Kit includes manifold, carburetor, gaskets and linkage

Redline Weber North America: Making the Right Weber Choice

Redline Weber North America - Weber 32/36 DGV & DCOE carbs, adapters, and intake manifolds A-series 40 DCOE kit: K 625 A-series Cannon single DCOE intake: 99003.821

Cyberspace Auto - Sells Redline Weber kits. Complete DCOE kit for A-series $514.

K110

Weber K110 A12 twin DCOE Pierce Manifolds $1200

Weber K625 A14 single DCOE

* Pierce Manifolds $575 * Alamo $548

Linkage

Twin-Pull with Cannon small-diameter rod

Redline Weber linkage - Center Pull

Redline Weber Kit - Side Pull

Linkage depends in part on the manifold you use. Does it have bolt-bosses for linkage? Or does it have built-in linkage bar?

Side Pull

Tomei manifold Side Pull. Nismo/Tomei manifold have built-in bar towers and use a large diameter cross bar

Center Pull

Center Pull - Need the floating lever for the carburetors. In essence, a single throttle lever, with its own balance screw

Center Pull needs only one carb-pull, eliminating the separate throttle adjustments. The center floating linka has its own balance screw

Single Carb Linkage

Quadrant

Fan lever - Harada Shosho company

Throttle Lever

Universal carby throttle lever

Custom Linkage

Center Pull wheel and lever linkage - discussion: Throttle linkages

Jetting

For baseline tuning, follow the recommended jetting from a Haynes Weber carburetor manual, or another Weber book.

I borrowed an excellent book from the library: Weber Carburetors Owners Workshop Manual by Haynes UK. Amazon.com link). It has this in the back. The B210 specs should be a good starting point for a stock A14.

Conversion equipment jet setting Datsun B110 (A12) - single 40 DCOE 2Datsun B210 & F10 (A14) - single 40 DCOE 2

Choke size 27 Aux. venturi 4-5 Main jet 1-10 Emulsion tube F7 Air corrector jet 1-65 Idle jet 0-50 F9 Accel. pump jet 0-50 Accel. pump inlet valve with ex. orifice 0-50 Needle valve 2-00 Datsun 510 (L16) - single 45 DCOE 13

Choke size 33 Aux. venturi 4-5 Main jet 1-30 Emulsion tube F11 Air corrector jet 1-80 Idle jet 0-50 F8 Accel. pump jet 0-60 Accel. pump inlet valve with ex. orifice closed Needle valve 2-00 Datsun 510 (L16) - dual 45 DCOE 12

Choke size 33 Aux. venturi 4-5 Main jet 1-30 Emulsion tube F16 Air corrector jet 1-90 Idle jet 0-50 F8 Accel. pump jet 0-50 Accel. pump inlet valve with ex. orifice 0-55 Needle valve 2-25

Choke size 32 Aux. venturi 4-5 Main jet 1-35 Emulsion tube F15 Air corrector jet 1-70 Idle jet 0-55 F2 Accel. pump jet 0-40 Accel. pump inlet valve with ex. orifice 0-55 Needle valve 2-00u

Also see discussion Help????? tunning Weber 40 DCOE on a14

40 DCOE-151 redline #19550.174 baseline jetting 32 Venturis 4.5 Aux venturis 115 Main jets F11 emulsion tubes 200 Air correction jets 45F9 Idle tubes 40 Pump jet 50 Pump exh 1.75 Needle valve

huicho: SINGLE 40 DCOE ON A STOCK A15 ROUND PORT COMPLETELY STOCK A15 economy version(round port head) Main Venturi 32 Aux. Venturi 4-5 Main Jet 140 Emulsion Tube F-11 Air Corrector Jet 200 Accel. Pump Jet 60 Accel.Pump Inlet Valve with Ex. Orifice closed Needle Valve 200 Idle Jet 55F9. If you do not use an air filter: * 180 on the air correctors * 130 on the main jets

Process

Start with venturi/choke size. For dual-carbs (one barrel per engine cylinder) 28mm is good for max power with good flexibility at 6000 RPM with a 1.2-liter engine. Larger venturis will make good power, but with less flexibility (flat spots, poor part-throttle response). See Carburetor Sizing.

Next, set the float. Everything is affected by the float level, so do this first.

Float Settings Early brass float: 8 to 8.5mm Late plastic float: 12.5 to 13mm

In DCOE series, the main jet should start at 4 x venturi size. For example, with 30mm venturis start with 120 Main Jets.

The Air Correction Jet should be 1.25 to 1.50 of the Main Jets (some say main jet + 50). For 120 main jet, start with 165 Air Jets.

That much is easy (setting the air/fuel ratio which is around 13:1 for all engines). The trickier part, for which tuning to the particular engine is called for, is the transitions:

- When accelerating the pump jet and duration are the main factors

- Transition between idle circuit and cruise circuit is controlled by the Emulsion Tubes and Idle Jets. Do not attempt to fudge this by raising or lowering the float level. The Float Level should be set to the Weber specifications before any other tuning is done.

Warm the engine up fully and set the Idle Speed. For a stock factory spec engine, set the idle speed to 800 RPM. The speed screw should be 1/4 to 1/2 turn in after contact with lever maximum. If it won't idle down to 800 RPM something is wrong - most likely the throttle shaft nut has been overtightened binding the throttle. But it could also be the linkage is jamming (inspect carefully). An air leak can also cause a high idle (either loose carburetor parts, a bad gasket, or a leaking/cracked hose).

After setting the idle speed, adjust the idle mixture screw to Lean Best Idle.

- If setting Lean Best Idle requires the mixture screw to be turned out 1-1/2 turns or more, the idle jet is too lean. Replace Idle Jets with half-size larger.

- If the mixture screw is 1/2 turn out (or less) from seated the Idle Jets are too rich. Replace Idle Jets with half-size smaller.

- If the Speed Screw is out more than 1/2 turn, the idle system is lean. This will cause problems with tuning the carb, so fix it now by fitting larger Idle Jets.

See also: http://www.redlineweber.com/html/Tech/dcoe_adjustment_layout_typical_i.htm

![[Datsun 1200 encyclopedia]](/wiki/upload/wiki.png)